Products Categories

-

Marine and Offshore

- Marine Deck Machinery

- Marine Mooring Equipment

- Marine Anchoring Equipment

- Pushing & Towing Equipment

- Marine Outfitting Equipment

- Marine Life-Saving Equipment

- Marine Power and Propulsion

- Marine Auxiliary Equipment

- Marine HVAC System

- Marine Pumps

- Marine Valves

- Marine Electrical Equipment

- Marine Decorations

- Marine Hardware

- Offshore & Engineering Products

- Fishing and Diving

- Yacht Accessories

- Industry Products

Kidney Type Bollard

- Kidney Type Bollard

- Bollards for Dock and Harbor

- Capacity: up to 200 Tonnes

- Material: Casting Steel, Casting Iron, Casting SG Iron, Ductile Iron

- Working Time: 15-20 Years

- Accept custom made sevice

Share this:

Features: General purpose applications up to 200 tonnes. Suitable for steep rope angles.

Technology Data: The safe factor of bollard Is 3 time.The face angle of cable:-45~+45°(Vertical), 0~180(Horizontal).

The paintsystem: Depend on the need of dock. the color is incloud black, yellow and other.

Material Type: Cast Iron ,Cast Steel and Cast SG Iron.

|

Dimensions (mm) |

Standard Bollard Capacity(Metric Tonnes) |

||||||||

|

SBK-15 |

SBK-20 |

SBK-30 |

SBK-50 |

SBK-75 |

SBK-100 |

SBK-125 |

SBK-150 |

SBK-200 |

|

|

SWL |

15 |

20 |

30 |

50 |

75 |

100 |

125 |

150 |

200 |

|

A |

41 |

51 |

54 |

60 |

70 |

79 |

89 |

95 |

111 |

|

B |

194 |

216 |

257 |

264 |

298 |

340 |

375 |

410 |

457 |

|

C |

275 |

330 |

385 |

413 |

481 |

550 |

605 |

660 |

759 |

|

D |

325 |

390 |

455 |

488 |

569 |

650 |

715 |

780 |

897 |

|

E |

288 |

345 |

402 |

431 |

503 |

575 |

632 |

690 |

793 |

|

F |

50 |

60 |

70 |

75 |

88 |

100 |

110 |

120 |

138 |

|

G |

|

|

|

|

238 |

272 |

299 |

326 |

345 |

|

H |

|

213 |

258 |

226 |

381 |

436 |

479 |

523 |

543 |

|

I |

213 |

300 |

350 |

353 |

438 |

500 |

550 |

600 |

671 |

|

J |

88 |

0 |

0 |

88 |

0 |

0 |

0 |

0 |

112 |

|

K |

|

136 |

154 |

183 |

146 |

167 |

184 |

201 |

283 |

|

L |

|

|

|

|

218 |

249 |

274 |

299 |

345 |

|

M |

250 |

300 |

350 |

375 |

438 |

500 |

550 |

600 |

690 |

|

N |

125 |

150 |

175 |

188 |

219 |

250 |

275 |

300 |

345 |

|

Bolt Size |

M24 |

M24 |

M30 |

M36 |

M36 |

M42 |

M48 |

M56 |

M56 |

|

Bolt Length |

450 |

450 |

450 |

600 |

600 |

600 |

750 |

915 |

915 |

|

Bolt Qty |

4 |

5 |

5 |

6 |

7 |

7 |

7 |

7 |

8 |

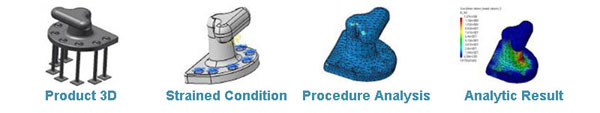

Quality Control :

The company strictly according to the ISO9001:2000 standard management and the production bollard as well as other variety's casting product, is under effectively the control and the management throughout in the manufacture product's process product's quality.

Production equipment: The company has the smelting electric stove 5 sets, yearly produces each kind of bollard as well as the other casting over 6000 tons.

Performance Test:

Design Standard :

People's Republic of China (2002) The Technical Code of Subsidiary Facilities for Wharf The standard JTJ297-2001

International Reference Standard :

Actions in the Design of Maritime and Harbor Works BS6349: Part 4 (1994).

Ministry of Transport, Japan (1999) Technical Note No.911 – Ship Dimensions of Design Ships under given Confi dence Limits.

EAU (1996) Recommendations of the Committee for Waterfront Structures.

Criteria for Movements of Moored Ships in Harbours – A Practical Guide (1995).

PIANC Report of PTC II-30 (1997) Approach Channels: A Guide for Design (Appendix B –Typical Ship Dimensions)

Product Testing Means:

Commonly Used Material Exchange Model :

Casting Steel (CN):ZG230、ZG250;ASTM/A27M(USA) BS3100.2-3(UK);JIS G5102(JP);DIN1681(Germany).

Casting Iron (CN): HT200, HT250; ASTM/A48UNC(USA) BS1450.(UK); JIS G5501(JP); DIN1691W-Nr(Germany).

Casting SG. Iron(CN): QT400, QT450; ASTM/A536UNS(USA) BS2789.(UK); JIS G5502(JP); DIN1693W-Nr(Germany).

Examination Standard Means:

JTJ-98 Standard of Quanlity Inspection and Assessment Fot Port Engineering Construction Assessment Fot Port Engineering Construction

Bollard Install Method(Reference):